HVO

HVO

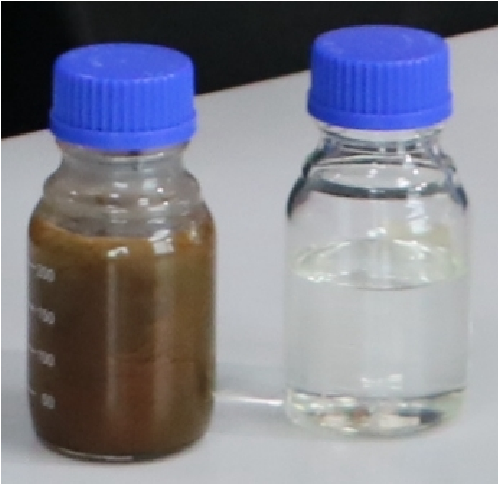

Waste animal and vegetable oils (mainly triglycerides) are mixed with hydrogen and hydrogenated under the action of catalyst to generate saturated alkanes, i.e. to obtain hydrocarbon based biodiesel.

Different from ordinary diesel

1. Low sulfur content: due to the low sulfur content in the raw material, the sulfur content of the product is less than 3ppm.

2. High flash point: the product is mainly C16, C17, C18 straight chain alkanes with high molecular weight and high flash point.

3. High cetane number: This product is mainly C16, C17 and C18 straight chain alkanes. Refer to the definition of cetane number, so the cetane number of this product is very high.

4. Low density: This product mainly contains C16, C17 and C18 straight chain alkanes with aromatic content less than 7%

5. Low nitrogen content: because the nitrogen in the raw materials is mainly reflected in protein, etc., the content is low.

The second generation biodiesel has excellent environmental protection characteristics

As the raw material itself does not contain aromatic hydrocarbons and sulfides that cause pollution to the environment; compared with ordinary diesel, the second generation biodiesel has the characteristics of environmental friendliness, with low emissions of organic matters in diesel vehicle exhaust, 20% of particulate matters, and only 10% of CO2 and CO emissions; its exhaust emission indicators can meet the EU emission standards.

Compared with the first generation of biodiesel

Animal and vegetable oils are mainly composed of saturated or unsaturated fatty acids. The technology of transesterification of animal and vegetable oils with methanol and ethanol to produce biodiesel (the first generation of biodiesel) has been widely studied by solid acid and alkali catalysis. The biodiesel produced is mainly long-chain fatty acid methyl ester or ethyl ester. Biodiesel is a renewable clean energy without sulfur, but compared with mineral oil, it has the following characteristics: firstly, it has high oxygen content, high viscosity and low combustion value, so it can not be directly used as internal combustion engine fuel. Secondly, a large amount of by-product glycerin will be produced in the process of transesterification, and the post-treatment of glycerin will increase the cost. Thirdly, it is difficult to deal with pollutants in the production process, so the market competitiveness of the first generation biodiesel is low.

In this environment, the second generation biodiesel production technology developed by our company, the hydrogenation biodiesel technology of waste animal and vegetable oil (fhdo), does not need to add methanol, no glycerin by-product, nor purification, and the cetane number is far higher than that of the first generation biodiesel. It can be said that the research and development of this technology, in response to national policies, solves the problem of the first generation biodiesel The disadvantages of biodiesel production technology further improve the quality of biodiesel, at the same time, the technology also greatly reduces the construction investment of the device. The application of this technology is also in line with the notice of the National Energy Administration on printing and distributing the development policy of biodiesel industry in the emergency document, which states that "we should adhere to the combination of independent research and development, introduction and absorption, basic research and commercial application, strengthen the construction of innovation platform, encourage the joint research and development of new high-yield energy plants, as well as the adaptability of raw materials and production process Clean, low energy and material consumption, high level of comprehensive utilization of advanced biodiesel technology and equipment.

Yangzhou Jianyuan Biotechnology Co., Ltd.

Telephone:15952590621

E-mail:328432157@qq.com

QQ:328432157

Address: No.8, Central Avenue, Yangzhou Chemical Industry Park (in Yizheng City)

Mobile website